Welcome to the world of dye sublimation printing! Home décor, soft signage and sports apparel markets have been experiencing steady growth, and dye sublimation printing is a great way for business owners to take advantage of this opportunity.

Below, we outline what dye sublimation printing is and share five takeaways you need to know before getting started.

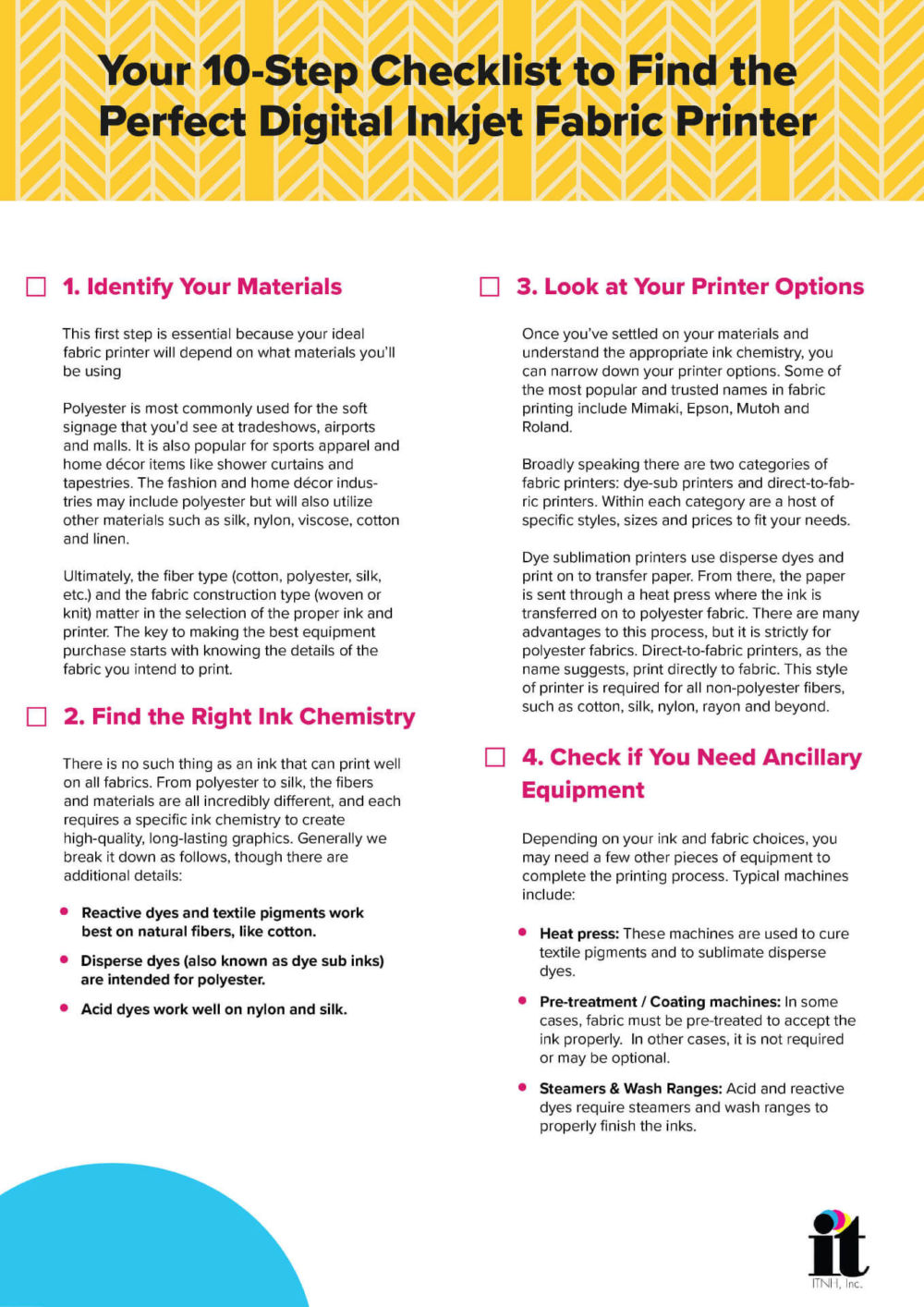

What is Dye Sublimation Printing?

It’s the chemistry behind dye sublimation that makes it the correct technique for printing on polyester and polyester resin coated products. Using a wide-format inkjet printer, dye-sub inks are printed on a special transfer paper. From there, the ink is heat transferred from the paper onto a fabric by using a heat press. The ink changes from a solid to a gas (hence the term “sublimation”) and enters the polyester fibers.

The polymers in the polyester bond when heated, which allows the graphics to quickly become permanently embedded into your materials. As a heated gas, the ink becomes fully infused into the fabric instead of just printed on the surface, resulting in long-lasting, high-quality products.

Compared to inkjet printing on other materials like paper or vinyl, dye sublimation is a more involved process since it involves multiple steps. But don’t worry. With the right knowledge, dye sublimation can be an enjoyable and profitable business. Here’s what you need to know to get started:

1. You Can Print a Huge Variety of Products

As we mentioned, polyester and polyester resin coated materials are the perfect substrates for dye sublimation printing. Since these printers are available in various styles and sizes, you can print on an assortment of products including:

- Home décor

- Upholstery

- Window Treatments

- Tapestries

- Pillows

- Sports apparel

- Jerseys and related sports gear

- Fashion apparel and accessories

- Dresses

- Scarves

- Ties

- Bathing Suits

- Hand bags

- Trade show and retail graphics

- Backlit graphics

- Silicone Edge Graphics (SEG): With SEG, graphics are printed on special fabrics that are designed to support a silicone strip on the edges. This is so that the print can be inserted into a frame, replacing the need for hard panel graphics. SEG gives trade show displays photo-quality imagery with a clean, frameless, clean appearance.

- Keepsake items

- Cell phone cases

- Mouse pads

- Coffee mugs

- Luggage tags

- Clipboards

- License plates

2. You’ll Need to Use a Specific Type of Ink

When you’re transferring your graphics from paper to fabric, the ink needs to convert from a solid state to a gas. Since the chemical process is very specific for dye sublimation, you’ll need to use a specific type of ink known as disperse dyes (commonly referred to as “dye-sub inks”).

These dyes are able to go from a solid state to a gaseous state in high temperatures and will easily bond to polyester fabrics.

The color gamut of disperse dyes is incredibly vibrant. And, some brands like Mimaki have introduced fluorescent inks that can be used to push the color gamut even further!

Since disperse dyes are permanently bonded to your finished products, the result is long-lasting graphics that are fully washable.

3. You’ll Need a Special Dye Sublimation Printer

While similar to other wide format printers, dye sublimation printers are specific to the dye-sub application. They use disperse dyes which are dedicated to print on transfer paper only.

Dye-sublimation is experiencing tremendous growth and there is a great selection of dye sublimation printers available from the best brands in the industry. Here are a few that the ITNH team highly recommend:

- Mimaki TS55: This 74” wide model is a leader in high-production sublimation printing.

- Mimaki CJV300-160 Plus: Combining high-quality, dye-sub graphics with contour cutting, the CJV300 is perfect for high-volume production on small items, like coffee mugs.

- Epson F6370H: Epson’s 64” roll-to-roll dye sublimation printer was designed for versatility.

- Mutoh RJ-900: This 42” entry-level model is a four-color, roll-to-roll printer, perfect for apparel and flags.

- Mutoh VJ-1638WX: A 64” model, this Mutoh printer is ideal for everyday printing on trade show materials, interior designs, apparel and more.

The wide selection of dye-sublimation printers available allows you to choose the perfect fit for your application and budget. Printers are available from 44” wide up to 10’ wide. Some are designed for the occasional job and others are capable of impressive factory production.

4. You’ll Need Additional Equipment

The dye sublimation process involves multiple steps, but they are simple and straight forward as long as you have the following items:

Heat Press

Your heat press is just as important as your dye sublimation printer. And just like your printer, heat presses are available in a variety of sizes, styles and price points. Here are a few of the most common types to give you an idea of what’s out there:

- Flatbed Press: If you’re transferring onto solid objects, a flatbed press is your best bet. Plus, they are great for printing t-shirts that require “all-over” designs.

- Calender Press: These presses use oil or electrically heated drums for heat transfer and are intended for apparel, décor and soft signage. Calender presses are best for high-volume printing.

Cutting & Sewing

Depending on your particular desired application, you may consider cutting and sewing options. Like the printer, these items range from simple and relatively inexpensive to large factory equipment. It’s best to talk with an expert to learn more about the equipment that will be your best fit.

5. Dye Sublimation is Affordable

With the assortment of equipment needed and the multi-step process, dye sublimation printing was once expensive and intimidating. The printers alone could run as high as $20,000, and that’s not even including the cost of a heat press.

Now, the market has expanded to give people more options to choose from and the cost of the equipment has been dramatically reduced. The technology has also improved, making the sublimation process much easier with even higher quality printing.

Some of the best names in dye sublimation printing, like Mimaki, Epson and Mutoh, now offer printers at $10,000 or less. And if you consider the potential that dye sublimation printing has for your revenue stream, this investment will be well worth it.

Frequently Asked Questions

Q: How much does a dye sublimation printer cost?

A: You can find dye sublimation printers from the top brands (Epson, Mimaki, Mutoh, etc.) starting under $10,000. They’ll get more expensive as they get bigger and faster. Also, keep in mind that you will also need additional equipment — like a heat press or a cutting machine — so your total package investment will be more than the cost of the printer.

Q: How long will a dye sublimation printer last?

A: As with anything, the higher the quality of your printer the longer it will last. A high-quality dye sublimation printer should have a lifespan of 10 years.

Q: How long with my dye sublimated item last?

A: Since the sublimation process involves the inks being chemically bonded to a material, decorated items permanent and washable. Fade resistance can vary from ink to ink and this should be discussed with a professional in the context of your application.

Q: How will I know how long an item should be sublimated for? And what temperature should the printer be?

A: This may take some trial and error since it will depend on the product you’re customizing. Typically, the following times and temperatures are recommended:

- For Polyester Fabric – 400F for 40 seconds

- For Hard Goods – We recommend a case-by-case trial

When in doubt, contact the printer manufacturer or your product supplier to get the right settings for your items.

If you need help getting started with dye sublimation printing, you can always use our free Printer Match Tool to find the printer that’s the best fit for your business. Or, you can contact us anytime for advice or recommendations.