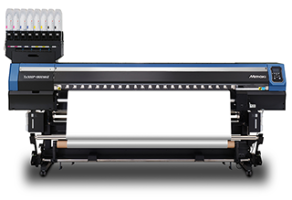

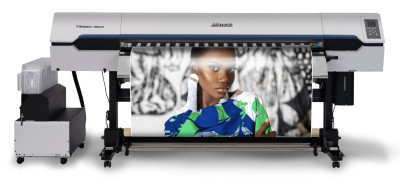

Digital inkjet technology has many benefits for printing on fabric. The high print resolution is remarkable and the creative design opportunities are endless. This means you can eliminate repeats and small run jobs, and customized items can be printed more profitably.

It is absolutely amazing to think that 20 years have passed

since ITNH and Mimaki worked together to sell the very first

Mimaki UV Flatbed Printer in North America in November 2004!

Visit the blog to learn more.