Braille & ADA Signage: Printers & Engravers

Creating custom signage that is compliant with the Americans with Disabilities Act (ADA) and braille requirements is a profitable opportunity for sign and graphics shops.

Our ADA and braille signage machines — including both printers and engravers — are available in compact, user-friendly designs and are ideal for a variety of materials. Enjoy direct-to-substrate printing, precise dot spacing and the cleanest cuts for your braille and raised letter products.

Braille & ADA Signage Printers

Printing ADA-compliant signage and braille requires a speedy flatbed UV inkjet printer, high-quality UV inks and software with pre-set ADA specifications.

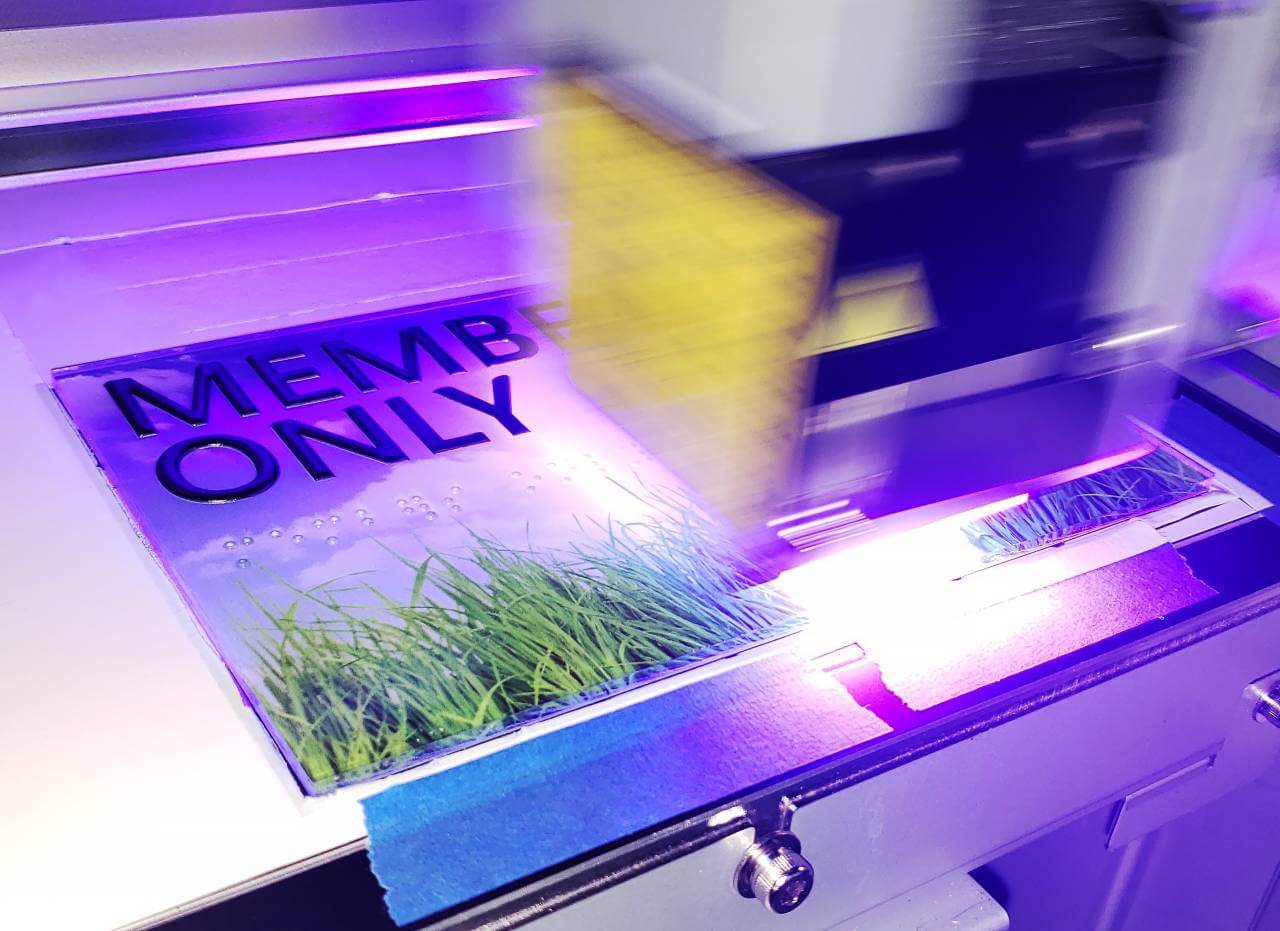

UV printers use a multi-layering ink process to create thick, raised textures such as lettering or braille. For speed and efficiency, it’s important to select a printer that can apply thick layers of ink as quickly as possible, such as a bidirectional printer.

Compliance is key when it comes to ADA signage, and a printer’s software can make all the difference. Your printer’s software should be pre-set with current ADA requirements for the height, curvature, spacing and other specifications.

Using a printer for ADA signage is a hands-off process. You can add multiple signs to the print bed (anywhere from 10 to 20 signs, depending on the bed size) and walk away while the printer does all the work for you. Graphics, raised letters and braille are all printed in one pass. It's common for shops to purchase engravers to create ADA and braille signage, but these machines can’t print graphics or images. By investing in a printer for ADA signage, you can do it all with one machine.

| Features & Benefits |

Applications |

|

|

Braille & ADA Signage Engravers

You can also add braille and ADA-compliant raised lettering to your prints with a laser or rotary engraving machine.

If you choose to use an engraving machine, you will need a flatbed printer to first create your prints. The engraver would then add the finishing ADA-compliant touches. Much like braille and ADA signage printers, the software that comes with your engraver must feature up-to-date ADA specifications to create compliant products.

Engravers are the traditional, proven method for creating ADA and braille signage. Engravers can be a fast and efficient tool, though they do require more operator attention and require a more manual process. These machines also allow you to use a variety of materials that you may not be able to for printing, like stainless steel. In this instance, engravers can also be more suitable for certain materials that are required for outdoor signage.

| Features & Benefits |

Applications |

|

|

FAQs

Q: Where is braille required?

A: Not all ADA signs require braille. However, any sign that identifies a room or area that is accessible to the public or employees requires braille. Examples include restrooms, classrooms and meeting areas.

Q: What are the ADA requirements for signage?

A: The ADA sets strict guidelines for the size, text, placement, colors, pictures and finishes of public signage. ADA signage must feature both visual and tactile text elements, which includes messages in raised letters with braille directly below. For specific guidelines, read the ADA’s Accessibility Guidelines.

Q: Should I get a printer or an engraver for my ADA signage?

A: This ultimately comes down to your workflow preference. The printing process is very quick — you can set up 15 signs on the flatbed, begin the workflow and come back 30 minutes later to the finished products. Engraving is a manual process, and someone will need to man the machine throughout the entire workflow.

It’s important to consider that an engraving machine can’t create prints; if you’re planning to design custom, creative signs, you’ll need an inkjet printer to get started.

Not sure what model you need? Let us know and we’ll guide you in the right direction.

Contact Us Now