From cotton and silk to nylon and polyester, different fabrics require specific ink chemistry. That’s why selecting a fabric printer that aligns seamlessly with your application is crucial to ensuring optimal print quality, durability and color vibrancy. With advancements in fabric printing technology for 2025, businesses have more options and improved capabilities at their fingertips.

In this blog post, we compare some of the top brands and models in fabric printing to help you make the best choice for your business now and in the future.

What Type of Fabric Printing Machine Do You Need?

In your quest to choose the perfect fabric printing machine, understanding your specific needs and the capabilities of different machine types is essential. In 2025, the digital textile printing landscape is more scalable than ever — with entry-level machines and consumables more affordable than ever and a wider range of models designed to support business growth at any stage.

Here’s a quick rundown of the fabric printing machine types we’ll focus on in this guide:

- Direct-to-Fabric Printing Machines: These machines work best for natural materials such as cotton and silk and synthetic ones like nylon. They’ve been engineered to provide the precise ink chemistry required for a vibrant, long-lasting print on these fabrics.

- Dye Sublimation Printers: If your business frequently prints on polyester materials, these printers should be at the top of your list. They use a special heat transfer process to sublimate dye into the fabric, resulting in high-quality, durable prints.

- Hybrid Printers: These machines combine the capabilities of direct-to-fabric and dye sublimation printers, enabling greater versatility in printing on different materials.

- Direct-to-Film (DTF) Printers: DTF technology involves printing designs onto a coated transfer film, which is then heat-applied to a wide range of surfaces. Depending on the printer and ink type, DTF can be used for everything from garment decoration (like t-shirts and sportswear) to hard goods such as drinkware, metal and glass — especially with UV DTF systems. However, DTF is not designed for roll-to-roll fabric printing, which is the focus of this blog. It excels at spot graphics or decorating finished items, not continuous yardage or all-over textile applications.

Want to learn more? Check out our guides on DTF for garment printing and UV DTF for hard goods to explore which option is right for you >>

How to Print on Fabric

Before diving into the different machine options, it’s important to understand the fabric printing process. Here are the essential steps for digital fabric printing:

- Choose the fabric: Select a material suitable for your application, whether it’s apparel, home decor or a commercial use product.

- Pre-treat the fabric: Depending on the textile and ink used, you may need to pre-treat the fabric with a special solution to improve ink adhesion.

- Create your design: Use design software to create your artwork, keeping in mind the fabric type and printing method you will be using.

- Prepare the printer: Load your chosen fabric into the printer and make sure you have the correct ink type for the fabric.

- Print the design: Print your design onto the fabric using the digital fabric printing machine.

- Heat fixation or cure: After printing, the fabric will need to be heat-treated to fix the ink, either with an integrated or standalone heat press, depending on your machine.

Best Fabric Printing Machines for 2025

Mimaki has firmly established itself as a leader in digital fabric printing, offering one of the industry’s most diverse and scalable product lines. Whether you’re starting out or scaling up, Mimaki’s lineup provides solutions that balance print quality, production speed and long-term value.

Dye sublimation printing is an integral part of the textile market. Since it’s perfect for printing on polyester, it’s one of the most popular textiles used for soft signage at trade shows, airports and malls. Sports apparel and home décor items, such as tapestries and shower curtains, are also best printed using dye sublimation techniques.

Here are our picks for the top dye sublimation models currently available.

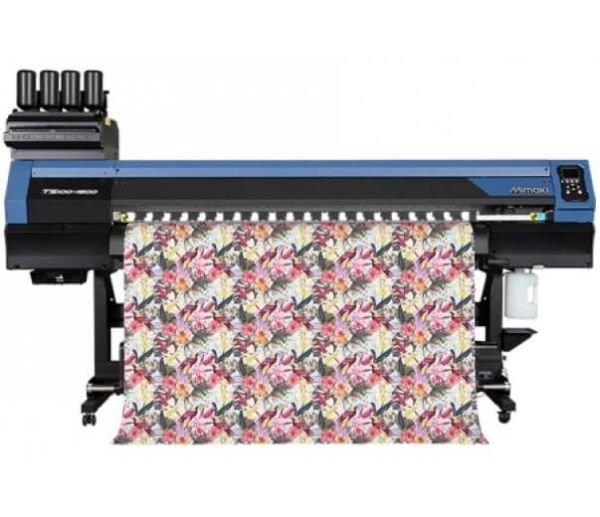

Mimaki TS 100-1600

The Mimaki TS100-1600 is a standout option for those seeking quality without breaking the bank. This machine is priced at around $10,000 and offers impressive value with its 64” width, bulking solution, inclusive software and take-up reel. Designed with simplicity in mind, users can expect a straightforward experience and the ability to print a couple hundred square feet per hour.

Pricing

MSRP: ~ $10,000

Compare to Mutoh RJ900

In comparison, the Mutoh RJ900, with an older design, is cheaper but only 42” wide and lacks the bulk system. Users would need to purchase the take-up reel separately. The TS 100 has notably attracted some of Mutoh RJ900’s clientele due to its comprehensive features.

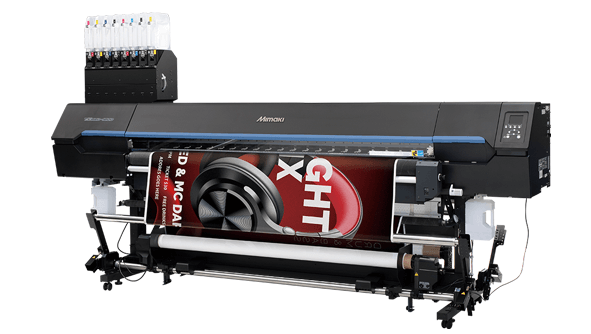

Mimaki TS 330P-1600

Priced in the mid $20k range, the Mimaki TS 330P-1600 stands out with its speed — about 2.5 times faster than the TS 100. This 64” wide printer offers a choice of eight colors, either running CMYKx2 or including fluorescents like yellow and pink.

Pricing

MSRP: ~ $25,000

Compare to Mutoh 1682

The Mutoh 1682 is a worthy competitor, but the TS 330 has the edge in color variation and speed.

Mimaki Tiger 600-1800TS

The Mimaki Tiger 600-1800TS is a game-changer, as it’s the first machine in the U.S capable of localizing production. Its breakneck speeds peak at 5,000 sq. ft. per hour, and even in production mode, it impressively churns out 3,300 sq. ft. hourly. The $140,000 price tag may seem hefty, but its ink costs are competitive, especially for production users. The design caters to both larger rolls (up to 600 lbs.) and the very lightest of papers (tests are ongoing for 20 gram paper). The lower ink and paper costs over time make it a savvy investment.

Pricing

MSRP: $140,000

Compare to MS JP4 and Epson

While these brands are strong contenders, the Mimaki Tiger 600-1800TS offers distinct advantages, particularly in speed and versatility.

Mimaki TX330-1800

The Mimaki TX330-1800 is a powerful hybrid printer designed for businesses that need the flexibility to print directly onto fabric and via transfer paper. Supporting both textile pigment and dye-sublimation inks, this model enables users to switch between media types without changing equipment, making it a go-to solution for mixed production environments.

What sets the TX330-1800 apart is its dual-ink and dual-media capability, which expands its utility across applications like soft signage, fashion, interior textiles and promotional goods. It’s a space-saving option that doesn’t compromise on performance, offering excellent color output and material versatility in a single machine.

The dual-head configuration reduces maintenance needs and contributes to faster print speeds without sacrificing quality. For businesses looking to grow or diversify their offerings without overhauling their workflow, the TX330-1800 offers the right mix of performance, adaptability and cost efficiency.

Pricing

MSRP: ~ $39,000

Mimaki TX330-1800B

The Mimaki TX330-1800B is engineered for precision textile printing on stretch, delicate, or unstable fabrics — the kind that standard feed systems struggle to handle. This model features a low-tack adhesive belt system that keeps fabrics flat and secure as they move through the printer, preventing edge curling, distortion, or skewing during print runs.

Ideal for cotton jersey, poly-spandex and other knit materials, the TX330-1800B is particularly well-suited for apparel applications where fabric stability is essential. It offers production-level throughput in a footprint that fits comfortably in smaller facilities, such as design studios or short-run manufacturing environments.

In addition to its mechanical advantages, the TX330-1800B helps lower operating costs thanks to its efficient ink delivery system and Mimaki’s waterless printing technology. It’s a smart entry point into direct-to-fabric printing for shops looking to scale responsibly.

Pricing

MSRP: $60,000

Note: As is evident from our list, Mimaki has made a substantial mark in the digital fabric printing space. Their consistent investment in research and development, diverse printer offerings and advanced inks emphasize their commitment to excellence and innovation in the industry, making them a standout choice for many businesses.

Please note: All prices listed reflect pricing at the time of publication.

Fabric Printer Comparison Table

| Model | TS100-1600 | TS330-1600 | Tiger 600-1800TS | TX330-1800 | TX330-1800B |

| Printer Type | Dye Sublimation | Dye Sublimation | Dye Sublimation | Hybrid (Direct + Transfer) | Hybrid Belt-Type (Direct-to-Fabric) |

| Print Width | 63.4″ (1,610 mm) | 63.4″ (1,610 mm) | 72.8″ (1,850 mm) | 74.4″ (1,890 mm) | 74.4″ (1,890 mm) |

| Max Speed | Up to 753 ft²/hr (70 m²/h) | Up to 1,453 ft²/hr (135 m²/h) | Up to 5,920 ft²/hr (550 m²/h) | Up to 710 ft²/hr (66 m²/h) | Up to 710 ft²/hr (66 m²/h) |

| Ink Type(s) | Sb610 Sublimation Ink (Bl, M, Y, K) | Sb411 Sublimation Ink (Bl, M, Y, K, Lbl, Lm, Lk); Sb410 (Fp, Fy) | MLSb510 Sublimation Dye Ink (Bl, M, Y, K) | Textile Pigment Ink (TP400) | Textile Pigment Ink (TP400) |

| Compatible Fabrics | Polyester (via transfer paper) | Polyester (via transfer paper) | Polyester (via transfer paper) | Cotton, Polyester, Blends (direct or via transfer) | Elastic and thick fabrics (e.g., apparel textiles) |

| MSRP (USD) | ~$10,000 | ~$25,000 | ~$140,000 | ~$39,000 | ~$60,000 |

| Best Use Cases | Entry-level sublimation printer; cost-effective solution for startups and small businesses | High-speed production with optional fluorescent inks; ideal for sportswear and soft signage | Industrial-grade printer for large-scale production; suitable for fashion textiles and interior décor | Versatile hybrid printer; supports both direct-to-fabric and transfer printing | Belt-driven system ensures stable printing on elastic fabrics; ideal for apparel production |

How to Choose the Best Fabric Printer for Your Business

When you’re choosing a fabric printer, the basics still matter: how much you need to produce, what materials you’re working with and how the equipment will hold up over time. Those practical factors continue to shape most buying decisions.

That said, there are a few recent and emerging developments that might influence how you think about your next investment, such as:

- Certified eco-friendly inks, such as OK Tech and Blue Sign-compliant formulations

- Waterless printing technologies that reduce environmental impact and wastewater output

- Domestic production strategies, including “Made in USA” capabilities to address tariffs and shorten supply chains

- Alternative transfer-based processes, like Mimaki’s TRAPIS system, designed for simplified, multi-fabric pigment printing with minimal maintenance

- Automation in finishing workflows, including cutting and SEG sewing for signage and retail display production

With those shifts in mind, here are the core criteria that still matter most when choosing the right machine:

Budget

Balance upfront costs with long-term value. Investing in a higher-quality machine can save money in the long run due to better efficiency and fewer maintenance issues.

Production Volume

Match the machine’s capacity to your business’s needs. High-speed machines are advantageous if you have large-volume orders, while smaller operations may benefit from more compact models.

Fabric Types

Ensure the machine is compatible with the types of fabric you plan to print on. Different machines and inks are suited to different materials, such as cotton, polyester, silk and nylon.

Expert Recommendations

Evaluate machine features and capabilities. Consult with experts or peers in the industry to understand the strengths and weaknesses of various models and brands.

Service and Maintenance

Reliable maintenance and service are crucial. ITNH provides service for Mimaki and Mutoh printers, ensuring you have the necessary support to keep your machines running optimally.

Learning and Ease-of-Use

Consider the training provided and the user-friendliness of newer models. Proper training is essential for achieving the best results.

Cost of Materials

Assess ongoing expenses for ink, transfer paper and fabric. Some machines may have lower upfront costs but higher long-term expenses.

Size and Space

Consider the machine’s footprint and how it will fit into your existing workspace. Opt for a smaller model if space is limited.

Speed and Production Capacity

Ensure the machine’s speed meets your business’s needs. High-speed machines are advantageous for large-volume orders

All-in-One Printers

Weigh the benefits and drawbacks of integrated heat fixation units. While they take up less space and can complete print jobs in one step, standalone heat-setting equipment may offer greater flexibility and longevity.

Find The Best Fabric Printer with ITNH

Still Not Sure Which Fabric Printing Machine is Right for You? Use Our Printer Finder Tool >>

We’re happy to answer any further questions you may have about dye sublimation or direct-to-fabric printers. Just contact us for advice!