Decorating, t-shirts, sweatshirts, bags, accessories or other types of finished textiles; today’s inkjet printer solutions are quickly becoming the method of choice for short & medium run, on-demand, multi-color designs.

Our garment decoration printing solutions are simple and straight forward. Anchored by the Epson F2100 Series, our selection of DTG printers includes user-friendly machines that are low maintenance and high quality with simple, step-by-step workflows. For those trickier fabrics, blends and other synthetics as well as those who are simply looking for an additional output for their Solvent, Latex or UV printers we recommend heat applied transfers, an easy to use and apply line of products with an unmatched feel.

Direct to Garment (DTG) Printing

This process has become increasingly popular in creating high-quality prints on a variety of fabrics including Cotton, Linen, Hemp and Bamboo along with many polyesters and poly blends. Though garments are the primary application, many users have found creative secondary products that work well with the water based textile pigments.

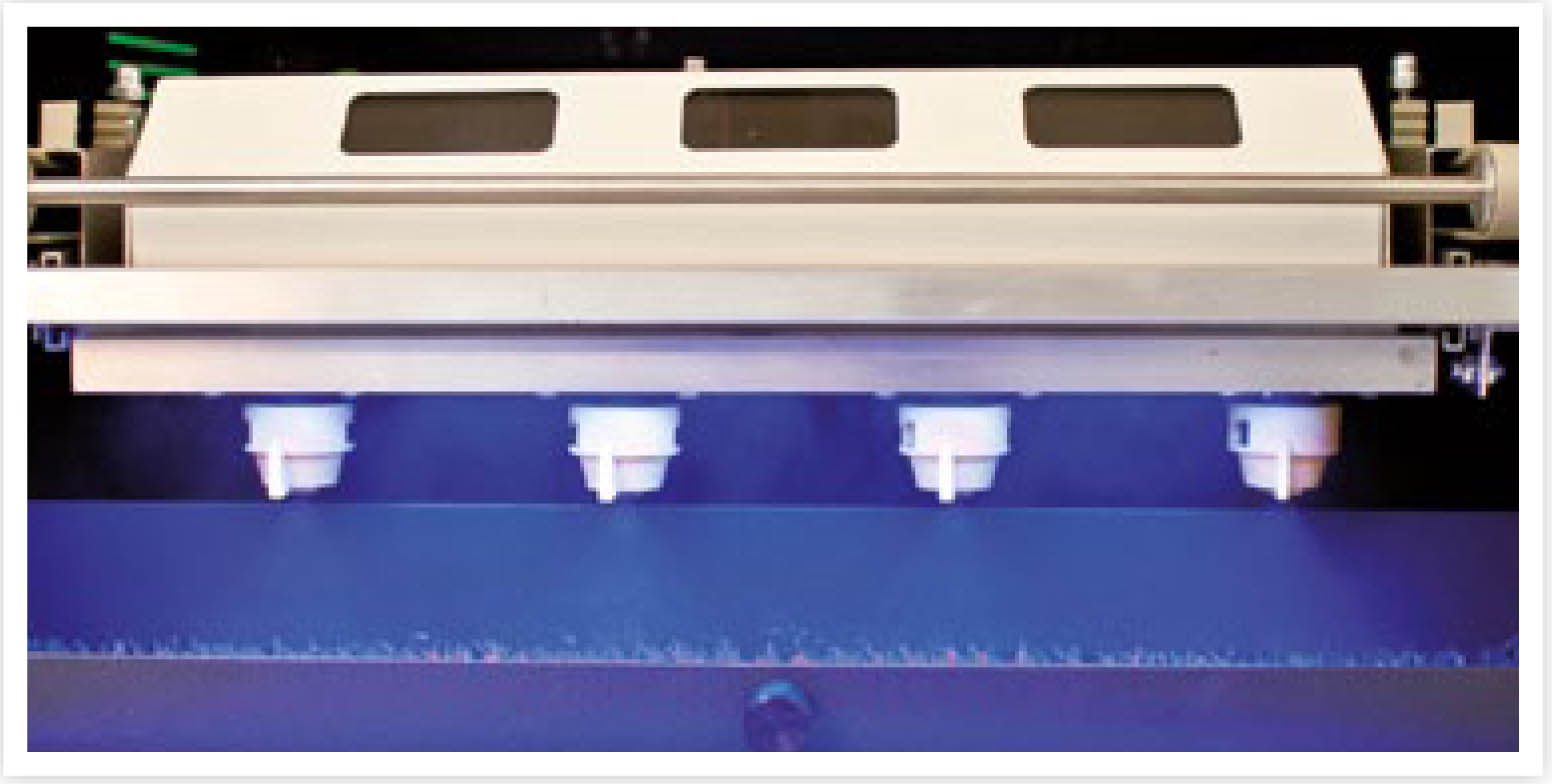

Automatic Pre-Treatment Machines

Designed for use with today’s DTG inks, these automatic sprayers provide consist quantifiable application of pre-treatments prior to printing with white ink as well as the application of anti-migrants for use with synthetic and wicking garment printing.

Heat Presses, Tunnel Dryers & Ovens

Whether curing inks and pre-treatment solutions or applying transfer films, heat presses are an essential part of the garment decorating process. For high volume scenarios, the additional of a tunnel dryer or oven can simplify the workflow and increase output.

Heat Applied Transfer Film

Our line of Results heat applied film is an industry leader in ease of application, compatible materials and temps all with the softest hand of any film on the market today. These are also a great option for maximizing applications by expanding the decorating capabilities of your solvent, latex or UV printers.

How We Work With You Learn More

By partnering with leading manufacturer’s covering nearly every inkjet application for more than two decades, ITNH has an unmatched industry knowledge base.

We pride ourselves on providing the right solutions for the right application. By listening to your decoration needs within your current products and product lines and balancing them with your future plans we can be sure to make the right recommendations for the right reasons.

We take the guess work out of product and equipment pairings. From material preparation to boards, vinyls and other substrates down to the inks, maintenance materials and finishing equipment, ITNH is here for all your needs.

ITNH Inc is a full line – full service distributor with technicians throughout North America. In addition to our break/fix capabilities our customers depend on ITNH for full solution support including workflow, software and color management assistance.